-

회사소개

-

ESG

-

사업분야

-

제품정보

-

고객센터

Future is on

다양한 자동화 영역에 각각 적합한 솔루션을 제공하기 위해 지멘스에서는 넓은 제품군의 자동제어기 솔루션을 제공 합니다. SIMATIC Controller 시리즈는 어플리케이션의 종류와 규모에 따라 Basic, Advanced, Distributed 및 Software Controller 형태의 다양한 제품군을 제공하고 있으며, TIA Portal 기반의 자동화 엔지니어링 기법은 거의 모든 영역에서 쉽고 빠르게 통합 된 엔지니어링을 할 수 있도록 강력한 프로그램 역량을 제공 합니다.

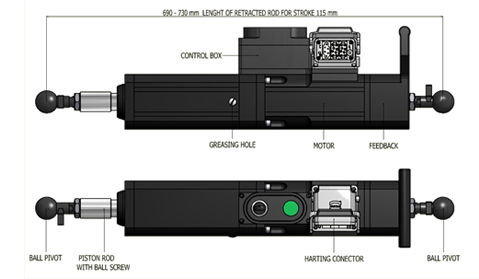

전력 범위가 0.12~6,840kW인 SINAMICS 저압 드라이브는 가장 기본적인 요구사항부터 다중 축 애플리케이션 및 기계 공구를 위한 최고의 동적 성능까지 광범위한 응용 분야에 적합합니다. 모든 디바이스는 전체 자동화 환경에 원활하게 통합되며, 매개변수는 표준화되어 있고, 작동 개념은 사용자에게 친숙합니다.

가변 및 일정 토크 특성을 갖춘 단일 모터 애플리케이션을 위한 범용적이고 간단한 MV 드라이브 컨버터 입니다. 시스템 통합을 위한 Drive Technology Configurator 및 빠르고 사용자 친화적인 시운전을 위한 STARTER와 같은 표준화된 엔지니어링 도구를 사용하여 단순성을 제공합니다. 경쟁력 있고 견고하며 서비스 친화적이라는 점에서 차별화됩니다.

가장 다양한 드라이브 작업을 위한 모듈형 주파수 변환기입니다. 구성 요소의 모듈 식 구조와 0.55 ~ 250kW의 넓은 전력 범위를 통해 개별 애플리케이션 및 산업 분야에 이상적인 컨버터를 항상 조립할 수 있습니다. 매우 안정적이고 유연한 모터 작동을 위해 펄스 폭 변조 기능이있는 최첨단 IGBT 기술이 특징입니다. 파워 모듈과 모터에 대한 높은 수준의 보호를 제공하며, SINAMICS Startdrive는 안전 기능을 시운전하는데 사용됩니다.

SIMOCODE는 프로세스 산업에서 저전압 모터를 관리하여 보호, 모니터링 및 제어 기능을 제공합니다. 중요한 데이터를 주시하고 안전한 모터 정지를 가능하게 하여 원활한 작동을 유지하는 데 도움이 됩니다. 이제 SIMOCODE 제품군에 새로운 추가 기능이 있습니다. SIMOCODE M-CP는 모터 제어 센터에서 사용하도록 특별히 설계되었습니다.

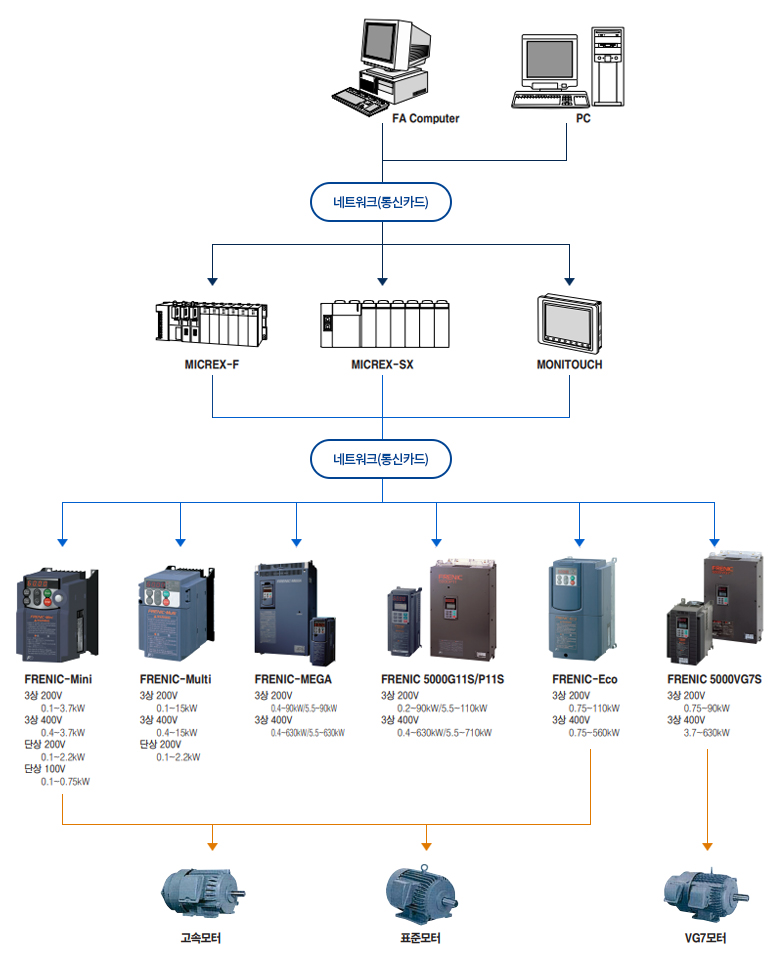

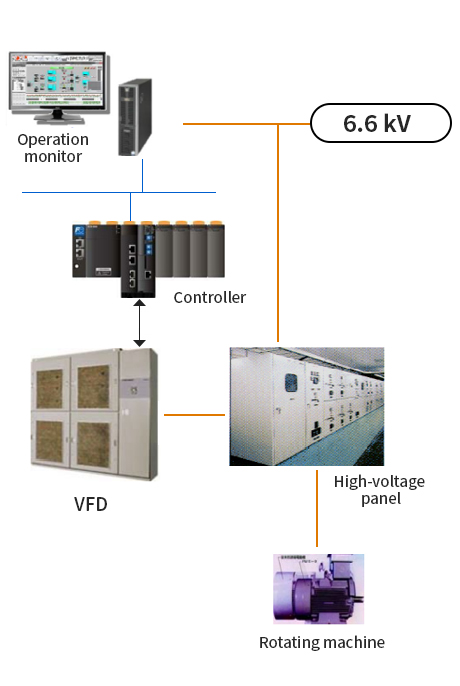

The FRENIC4600 series high-voltage inverters employ

international advanced electrical technology, have the cascaded

structure optimization design for multi-level units and are equipped

with highly integrated dedicated motor control MCU.

There is

no need to configure higher harmonic filters and power factor

regulating capacitors for them. They have very high reliability and

easy to operate and maintain.

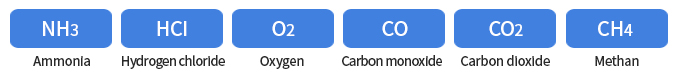

Electric power

Induced draft fan

Primary fan

Secondary fan

Blower fan

Condensate pump

Circulating pump

Feed pump

Coal mill

Metallurgy

Blast furnace fan

Sintering fan

Circulation fan

Dust removal fan

Descaling pump

Water sending pump

Circulating pump

Petrochemical

Compressor

Delivery pump

Refrigerator

Agitator

Municipal water conservancy

Water sending pump

Intake pump

Flood draining pump

Lift pump

Building materials

Circulation fan

High temperature fan

Kiln head and kiln tail exhaust fans

Mill and crusher

Rotary kiln

Others

Belt conveyor

Main fan

Hoist

Mixer

Testbed

Tube machine

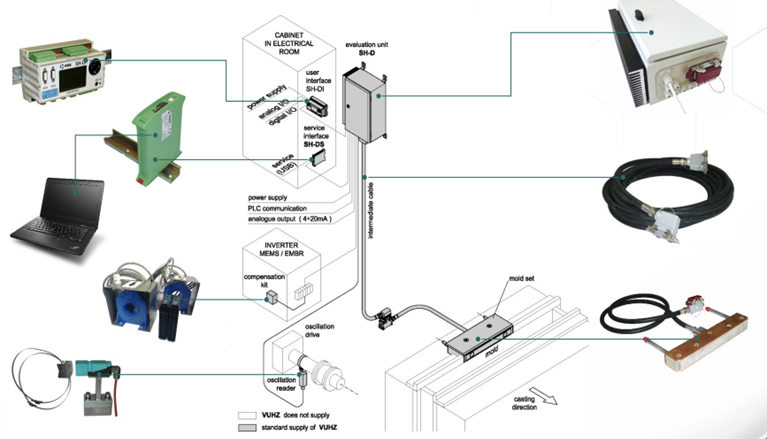

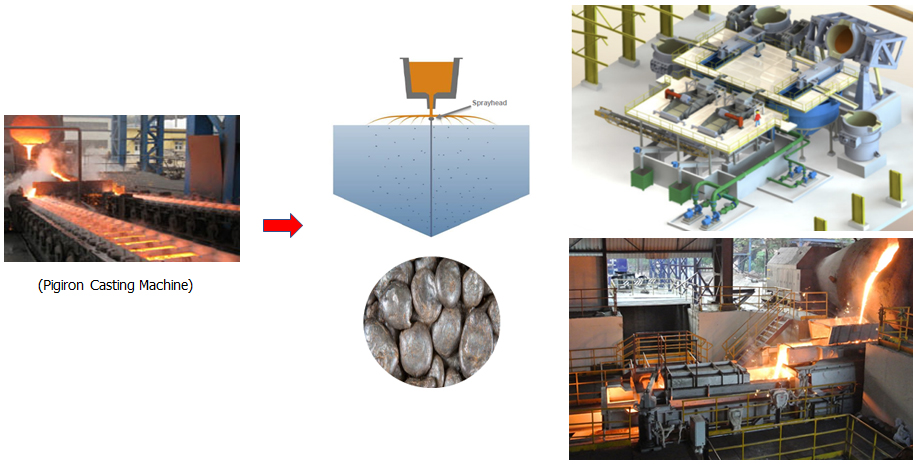

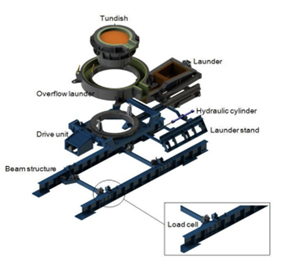

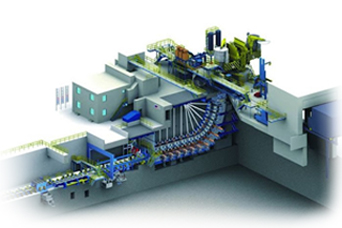

Ensuring stable operations at the BF is beneficial High Capacity GRANSHOT ensures stable BF operation

Ferroalloy producers find the GRANSHOT process attractive due to

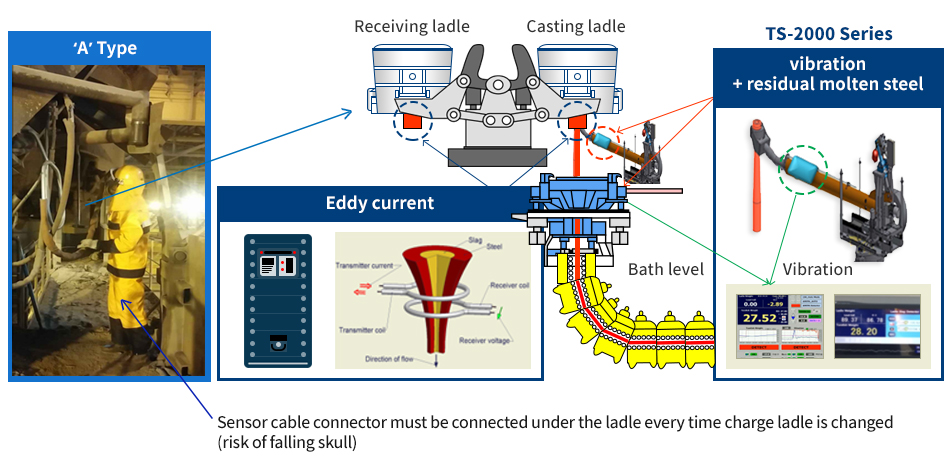

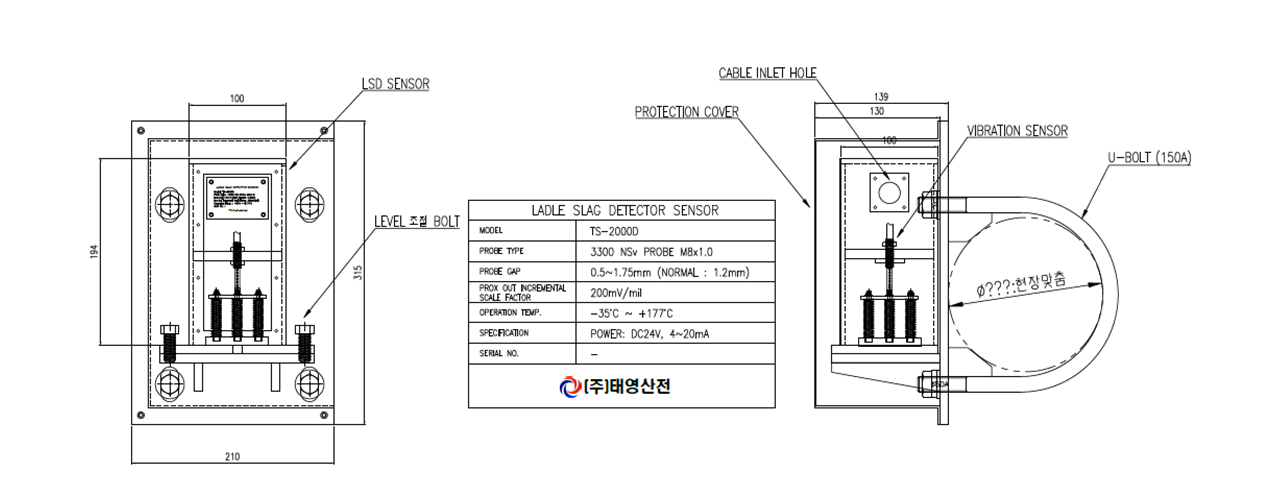

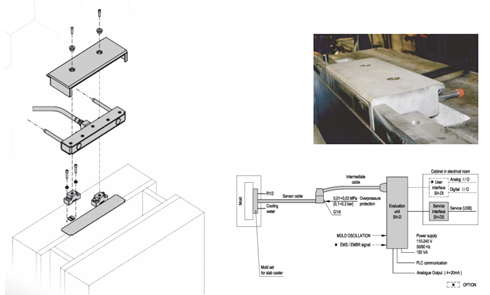

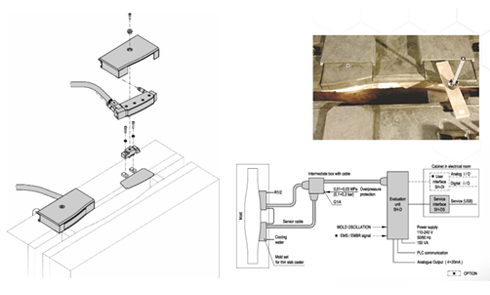

Optimized solution with high reliability compared to conventional vibration method

Operator action not needed